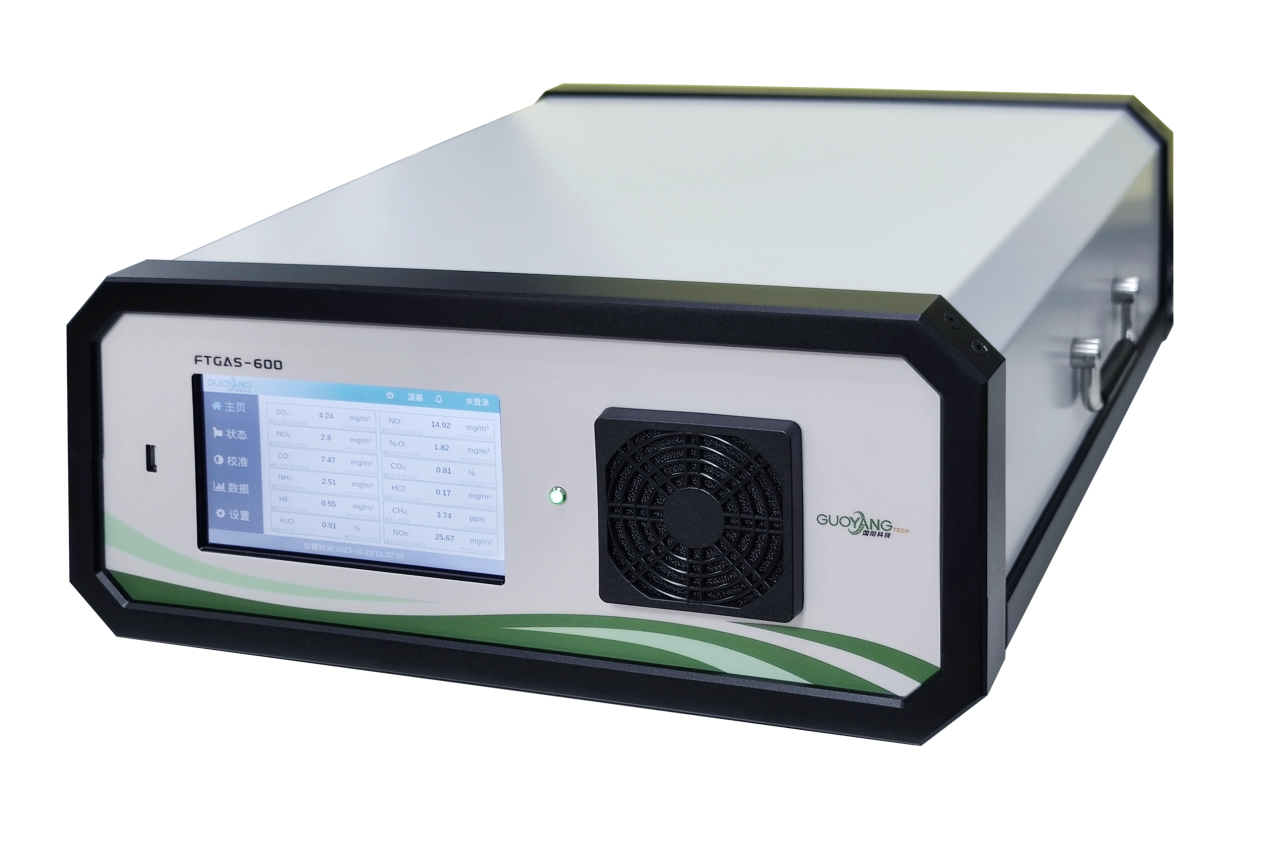

FTGAS-600 portable gas analyzer

FTGAS-600P

FTGAS-600P portable gas analyzer

FTGAS-600P portable gas analyzer is a portable Fourier infrared gas analyzer independently developed by our company for environmental monitoring and industrial site emission gas analysis. The analyzer is capable of measuring most gas pollutant concentrations and has the characteristics of high measurement accuracy, high stability and reliability, and fast response time.

Product features

- Interferometers are designed specifically for field applications, rugged and durable;

- HeNe reference laser have better wavenumber accuracy and stable compared to solid-state laser. This results in both increased detection precision and long term stability;

- Long path heated gas chamber with small volume, suitable for high humidity sample gas and reduce response time;

- High detectivity TE-cooled MCT detector;

- Modular design is employed for light source, spectrometer, core circuit, gas chamber, etc., and high reliability, good scalability and easy maintenance are realized;

- Built-in spectral analysis and concentration calculation algorithm, no external computer is needed to calculate component concentration;

-

High-temperature probes are suitable for gas sampling with dust or suspended particles, especially for measurements under non-static conditions;

- Contains a non-corrosive, heated, replaceable cartridge;

- The cartridge is housed in a thermally insulated, electrically heated stainless steel filter housing with a protective outer box;

- Temperature regulation is controlled by PTC heaters;

- The heated sample wire is connected directly to the probe housing with quick connectors

-

Small size, light weight, easy to carry;

-

Automatic temperature control, control accuracy 0.1℃;

-

Sampling is automatically stopped in case of heating failure to prevent system contamination;

-

Ensure high precision filter (0.1U), system pressure drop 6mbar. Humanized design, filter easy to replace;

Range

|

Components |

Range |

Extended Ranges |

|

CO |

(0~75)mg/m3 |

(0~2000)mg/m3 or higher |

|

CO2 |

(0~25)% |

(0~50)% |

|

CH4 |

(0~50)mg/m3 |

(0~5000)mg/m3 or higher |

|

NO |

(0~150)mg/m3 |

(0~2000)mg/m3 or higher |

|

NO2 |

(0~150)mg/m3 |

(0~2000)mg/m3 or higher |

|

N2O |

(0~50)mg/m3 |

(0~2000)mg/m3 or higher |

|

NH3 |

(0~50)mg/m3 |

(0~200)mg/m3 or higher |

|

SO2 |

(0~50)mg/m3 |

(0~2000)mg/m3 or higher |

|

HCl |

(0~75)mg/m3 |

(0~200)mg/m3 or higher |

|

H2O |

(0~40)% |

|

|

HF |

(0~50)mg/m3 |

(0~200)mg/m3 or higher |

Specifications

|

System |

|

|

Physical Dimensions |

435mm(D) x175mm(H) x435(D) |

|

Weight |

23Kg |

|

Power Requirements |

220VAC±10%/Max 2500W Ave 150W@ AT 25℃ |

|

Gas Temperature |

Up to 180℃ |

|

Operating Temperature Range |

0-40℃ |

|

Purge and Zero gas |

Nitrogen(99.999% or higher recommended) |

|

Warm-up Time |

<30 minutes |

|

Sample Gas Pressure |

Ambient |

|

Sample Gas Flow rate |

2 – 3 l/min recommended |

|

Sample Gas Filtration |

Minimum 2 µm particulate filtration |

|

Gas fittings |

Sample in: 6 mm Swagelok, stainless steel |

|

Sample out:8 mm Swagelok, stainless steel |

|

|

Interferometer purge: 6 mm Swagelok stainless steel |

|

|

Output Port |

Ethernet port |

|

Communication Protocols |

MODBUS,OPCUA |

|

Measuring principle |

FTIR |

|

Performance |

|

|

Zero Drift |

< 2 %@24 hours |

|

Span Drift |

< 1 %@24 hours |

|

Response Time |

Typically <100s@3L/min |

|

Linearity |

±1%F.S. |

|

Repeatability |

1%. |

|

Detection Limit |

<1% F.S. |